In today’s world, innovation and technical capability have become survival mechanisms – this is also true for steel tank fabricators. Innovation is often the answer to the unique challenges that arise when constructing large field erected tanks.

The challenges arise not only from logistics and planning, but also regarding process and equipment capacity. Erecting and welding these large steel tanks requires specialized processing equipment which can be purchased from a variety of welding and construction suppliers.

The Vertomatic: T Bailey's Innovative Vertical Seam Welding Machine

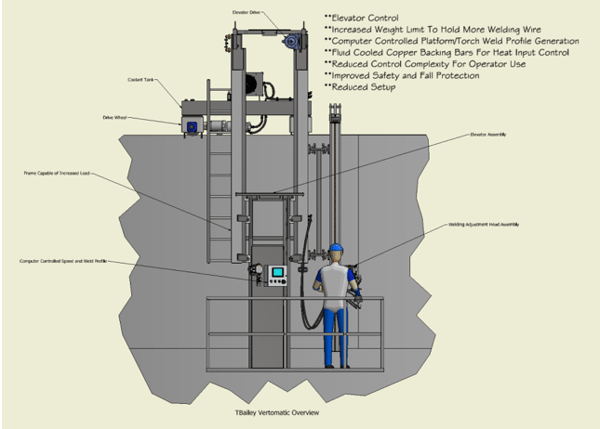

However, because of process requirements, the necessary equipment is not always available, and therefore must sometimes be created. The Vertical Seam Welding machine, otherwise known as the Vertomatic, is an example of T BAILEY LLC’s ability and capacity for innovation when faced with a challenge of this kind.

1. Example of commercially available Vert. Seam Welder.

For most storage tank fabricators, welding the vertical seams of a field erected tank is one of the more painful processes. Setup time, machine control accessibility, limited welding capacity, and safety were some of the reasons it became apparent to us at T BAILEY LLC a new machine design was desperately needed.

To solve these issues, T BAILEY LLC’s engineers went to work and constructed a completely new machine.

The result?

A tool that greatly reduces labor cost and set up time, increases productivity and quality, and makes the process safer for the operator.

What Does Innovation in Steel Tank Fabrication Look Like?

T BAILEY LLC reviewed the current design and identified many opportunities for improvement. The positioning of the operator was quickly identified as an opportunity for cost savings.

Machines that are currently commercially available create a situation where the operator is often placed in uncomfortable and un-safe positions. The operator needed a safe and comfortable place to operate the machine, which meant constructing a machine that had a movable platform with easy to use controls.

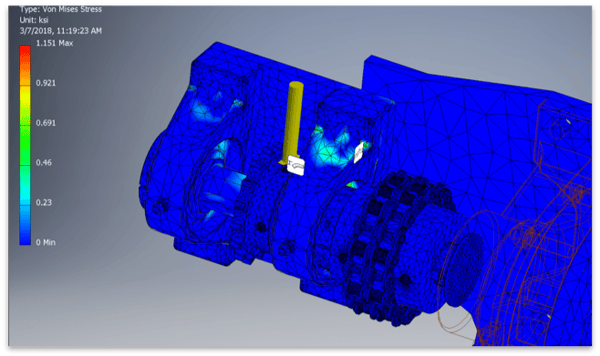

Partnering with Sumitomo Drive Technologies and using the latest 3D modeling software, the team developed an innovative drive system that would keep complexity to a minimum while providing a robust and safe system. Initial load testing of the system operated beyond the teams expectations and – with safety in mind – an internal fall protection system was added. As a result of the improvements the system performed better than expected while improving operator safety.

Innovation Must Lead to Increased Productivity

Innovation must ultimately lead to cost reductions through increased productivity and process improvements. Controlling a machine as complicated as a vertical seam welder presented the team with a chance to drive more cost reductions.

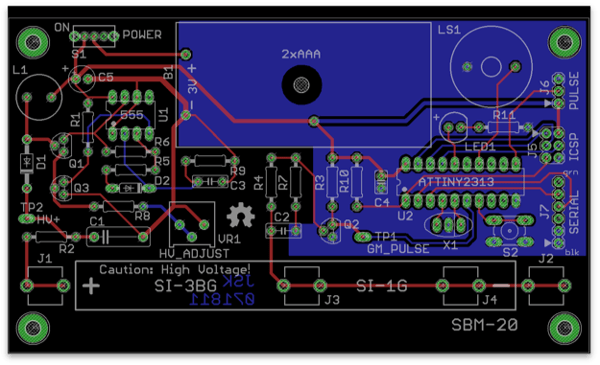

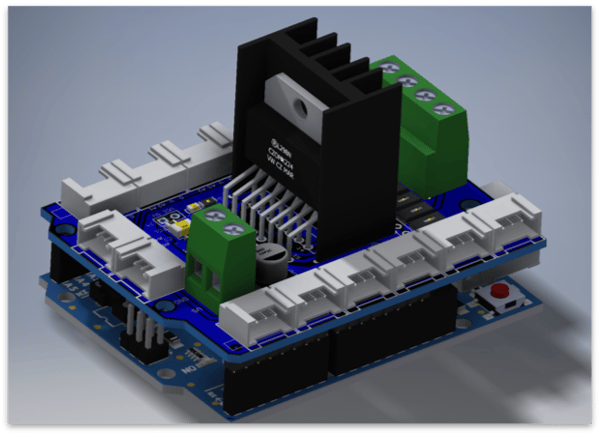

The T BAILEY LLC Vertomatic boasts a newly developed computer control system. Based on an ARM-Cortex M Processor, our upgraded design minimizes the number of controls the operator has to manage. In addition, it presented an opportunity to automate control of the welding process itself which increased the quality of the weld.

The upgraded design makes 15,000 adjustments per second to speed and welding parameters to ensure the best possible weld. Due to the explosion of 3rd party rapid prototyping shops and open source hardware platforms, the team was able to develop and produce the circuit boards necessary without the expense or time typical of such an endeavor.

T BAILEY LLC utilizes an internal base of software from sensor drivers to motion control timing algorithms. Using our repository of software, the costs and time needed to develop the system was kept to absolute minimum.

Time Is Money: Is It Increasing Productivity?

When taking on large design projects, such as the development of the Vertomatic, our goal is always to complete the project efficiently as possible. This means we don’t want to re-invent the wheel. To save time it's often possible to modify pre-existing equipment instead of building it from scratch. Like many innovations we've accomplished in the past, the Vertomatic project necessitated the need to alter pre-existing welding equipment.

Our decades of experience and 3rd party partnerships provide us with the necessary skills and tools to work with industry standard equipment in such a way. The T BAILEY LLC Vertomatic uses a Bugo-Systems tractor to drive the welding torch up and down the weld seam. Unfortunately, Bugo does not produce a tractor that accepts a computer signal for external control.

However, because of our experience working with Bugo Tractors, the necessary modifications were made in a single day. A small electronic module was built and added so that our maintenance team could easily support the altered machine. Having the ability to modify the Bugo saved months of design work and lowered the project costs.

Again, utilizing modern CAD and simulation tools allowed for another improvement to the machine that ultimately transfers to lower costs for our customers.

Providing Value Through Innovation

One way T BAILEY LLC has chosen to maintain competitive advantage is though technical innovation. Welded steel tank fabrication has traditionally lived in a non-technological world, existing somewhere in between custom fabrication and classical manufacturing. The Vertomatic is just one of the many examples that demonstrate our commitment to value and quality.

As the world becomes a more integrated and competitive community, T BAILEY LLC continues to push boundaries, challenge classical thought, and drive ourselves to offer more value to the customers we provide for. Every success we have contributes to the service and value our customers expect.