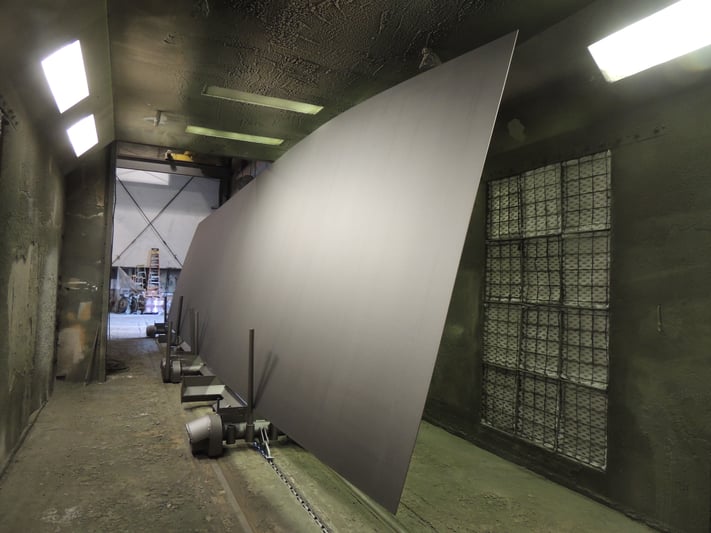

The surface preparation of steel is the first critical step to ensuring a coatings project is going to last a long time. Before the project can begin it is important to remove mill scale and any other contaminants present on the surface to be coated. The mill scale is the flake surface of hot rolled steel that is present after the steel is forged. Removing surface contamination is critical as it impacts the adhesion of a coating system. Blasting is meant to provide an anchor profile for coatings to adhere too. T BAILEY LLC has a 16’ x 80’ enclosed climate-controlled building to ensure proper surface preparation is performed.

Two Surface Preparation Methods for Different Purposes

Two different methods or approaches of blasting surface preparation are manual hand blasting and automated blasting. Each method is used for different reasons.

Hand Blasting is Flexible and Has Deployable Options

Hand blasting is a manual process. This process deploys trained operators with equipment to perform the cleaning and blasting operations necessary to meet an individual product specification usually outlined in a manufacturer's product data sheet. Hand blasting is not limited to simple shape or size like the automated counter part process.

How T BAILEY Does Manual Blasting

The manual hand blasting operation T BAILEY LLC uses incorporates steel grit to reach a specified anchor profile for coating operations. T BAILEY LLC has the capability to hand blast complex structures of all shapes and sizes. The blast room is equipped with ventilation, LED lighting and automated lifts to reach heights of 18’. The blast media is reclaimed, cleaned, and reused, cuttings costs compared to other operations that use sand which breaks down and can only be used once. Hand blasting is typically performed on larger objects that are already fabricated or erected.

Automated Blasting Systems Helps to Remove Human Error

The automated blasting process is very advantageous to repetitive simple processing. This process deploys a specific setup or envelope to maximize efficiency over a part with very high levels of repeatability. The equipment & facility setup is typical for larger batch operations performed often by coatings companies. Automated blasting operations are a very thorough cleaning operation, however they are still dependent on trained operators to verify proper cleaning of the part, ensure the mix of the media to achieve proper profile, and monitor the equipment for preventive maintenance. The automated blast removes the human element of light or missed spots that comes with hand blasting.

How T BAILEY Does Automated Blasting

T BAILEY LLC employs the use of an automated surface preparation system manufactured by Wheelabrator™. This system utilizes eight motor-driven centrifugal paddle wheels that power the blast media onto the surface to be blasted, which is driven by a custom cart(s) & track system that provides a quick, efficient and uniformly prepared steel surface for application of coatings. The Wheelabrator™ can be set too three speeds, depending upon the cleanliness requirements. Once set, the Wheelabrator™ fluctuates very little while it reuses a combination of steel shot/grit mix to continually feed the eight blast wheels, run by two operators.

Finish or Desired Cleanliness of the End Product

Manufactures of coatings and other specifying agencies also recommend and sometimes require a specific surface cleanliness to a standard. In the United States, these standards are typically outlined by NACE (National Association of Corrosion Engineers) or SSPC (The Society for Protective Coatings). Most commonly, any specified finish requirement is visually inspected in accordance with the SSPC Vis 1 standard.

Some of the difference between surface finish of the most common requirements are outlined below:

SSPC-SP5 / NACE No. 1 White Metal

100% free from all visible surface staining. This degree of cleanliness is necessary anytime there is application of a high-performance protective system.

SSPC-SP10 / NACE No. 2 Near-White Metal

95% free from visible surface staining. Created as a cost effective alternative to SSPC-SP5/NACE No. 1 for metals that are exposed to harsh conditions.

SSPC-SP6 / NACE No. 3 Commercial Blast Cleaning

66% free from visible surface staining. Light shadows, slight streaks or minor discolorations from rust, mill scale or other types of stains are permitted.

T BAILEY LLC Has the Best of Both to Meet Your Upcoming Project Needs

Creating a profile with surface preparation for the coatings to anchor to is an essential start to ensuring your project turns out properly. T BAILEY LLC has NACE Level II/III inspectors implementing a quality control program that adheres to standards that are specified in the industrial paint coatings design. T BAILEY LLC will ensure that the proper blasting method is used, whether it be manual hand blasting or an automated blasting process with a Wheelabrator™.